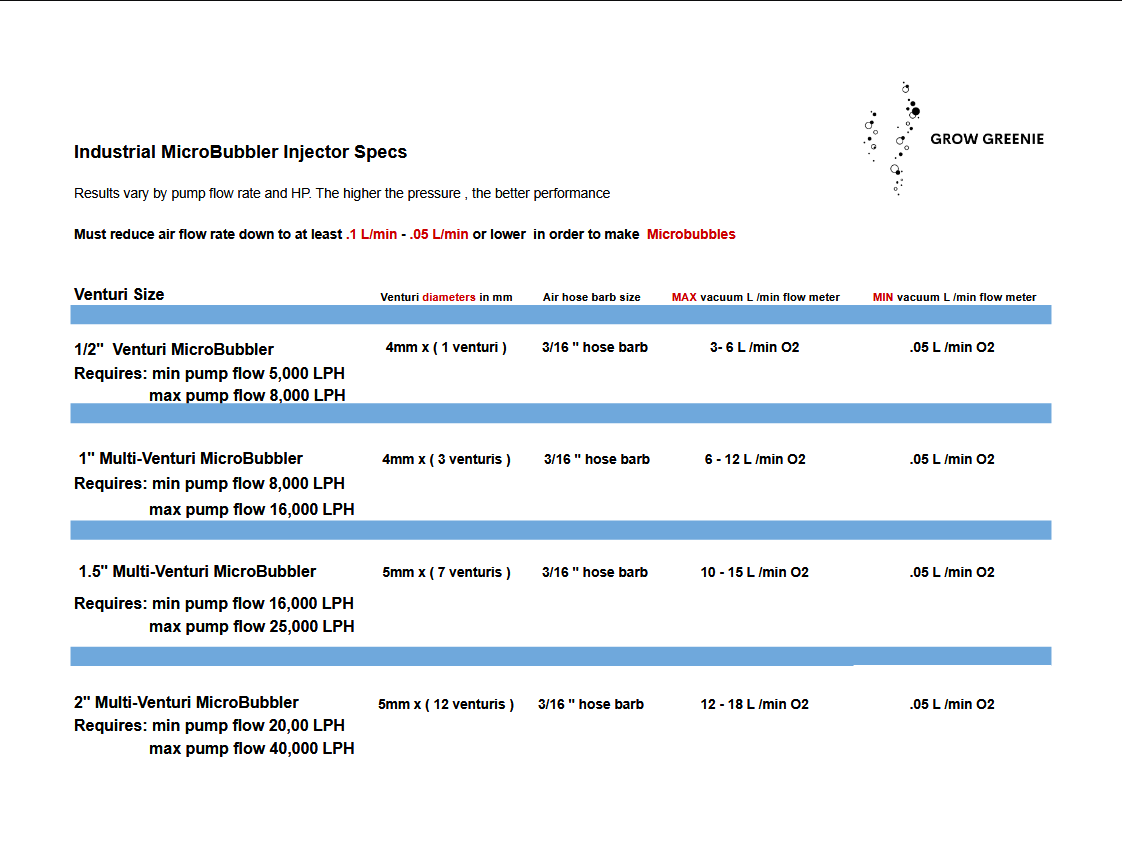

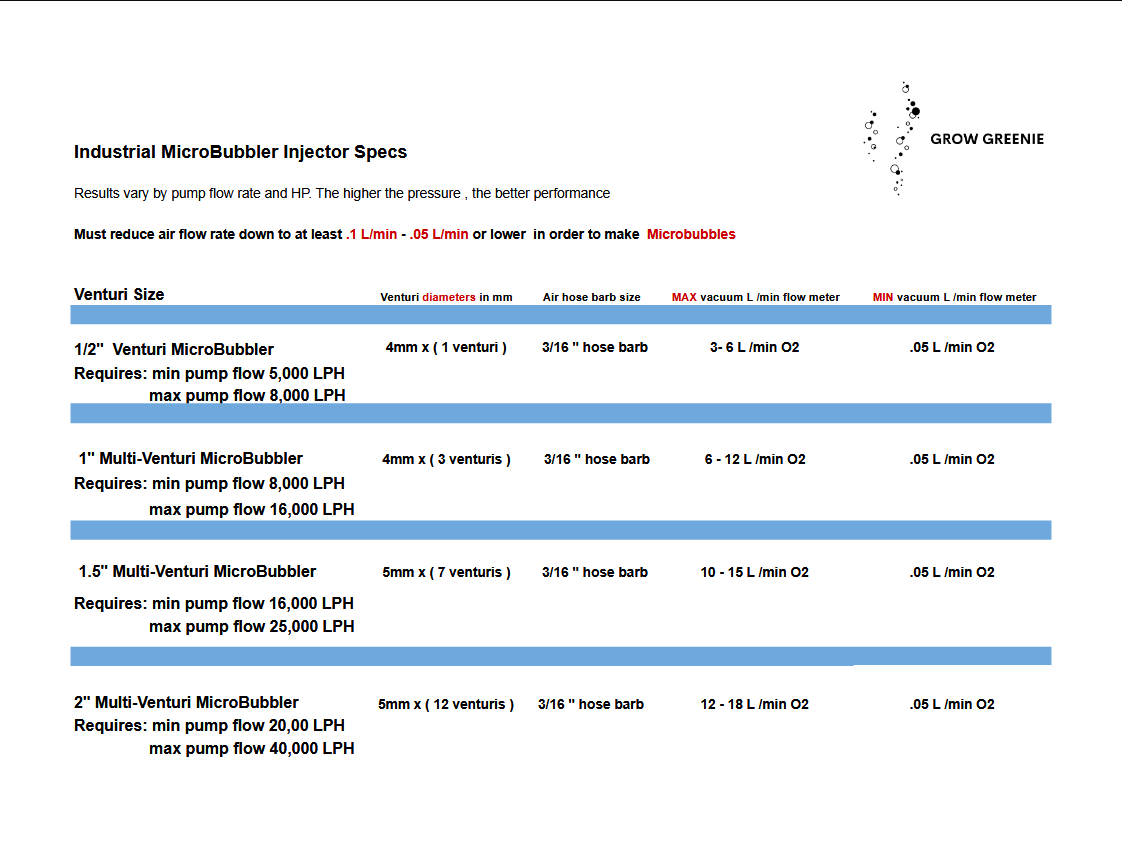

Pump Requirements & Flow Rate

-

1" MicroBubbler

minimum pump flow rate of 8,000 L/H (2,100 G/H)

-

1.5" MicroBubbler

minimum pump flow rate of 16,000 L/H (4,200 G/H)

-

2" MicroBubbler

minimum pump flow rate of 20,000 L/H (5,200 G/H)

Maintenance & Operation

Must use the included air hose flow valve to reduce air flow: This reduction in air flow is what creates the microbubbles.

DO NOT REMOVE the threaded nipple on the outflow side - it is crucial for creating suction. When using as a jet head, keep the outflow nipple on or use an extension of PVC piping to bypass back into the main line.

You will need a 3/16" air hose

Included: An air hose flow valve (to control bubble size) and back flow check valve.

Maintenance: Use compressed air to blow into the air inlet. This will help blow out any debris built up on the inside.

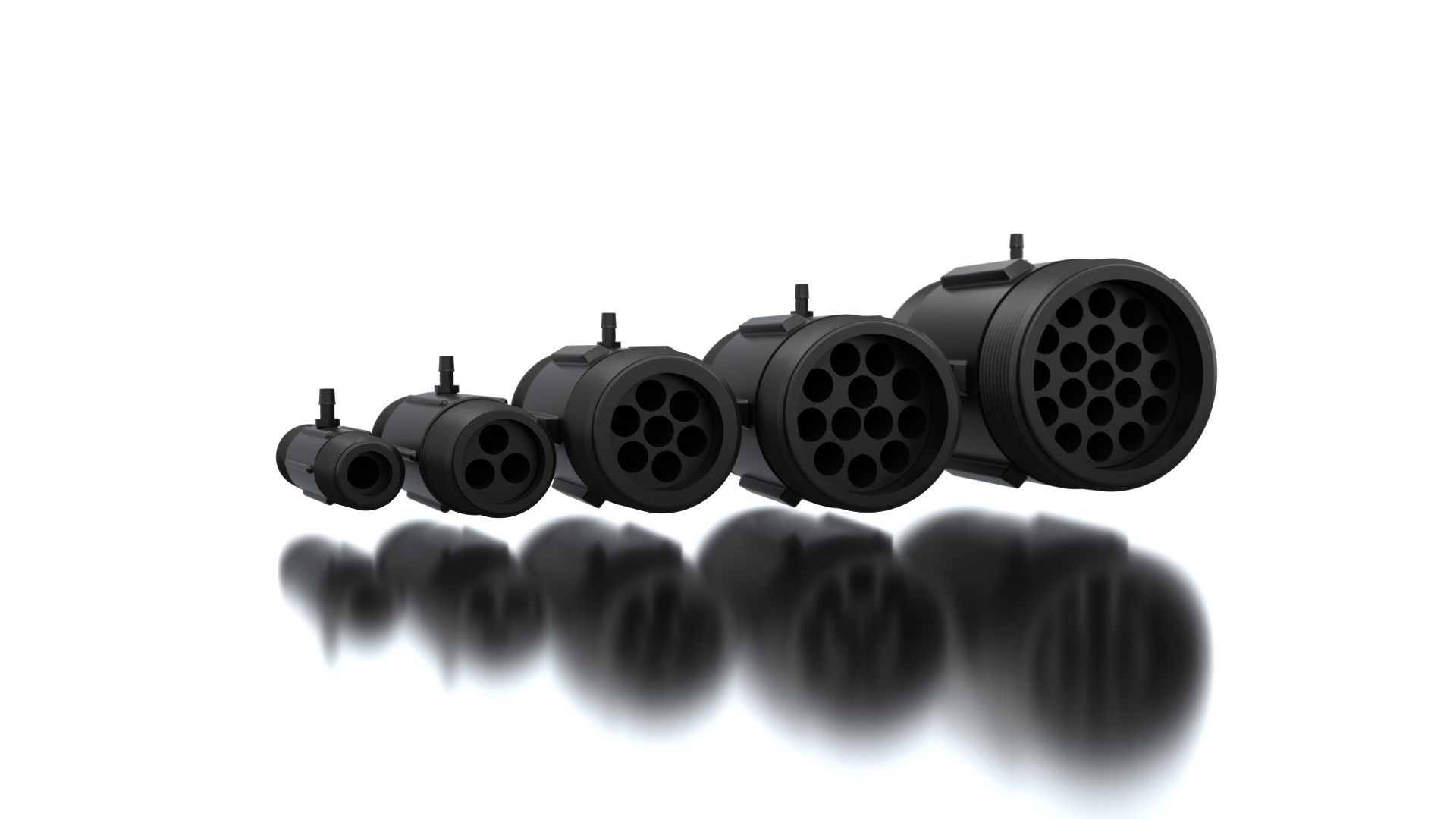

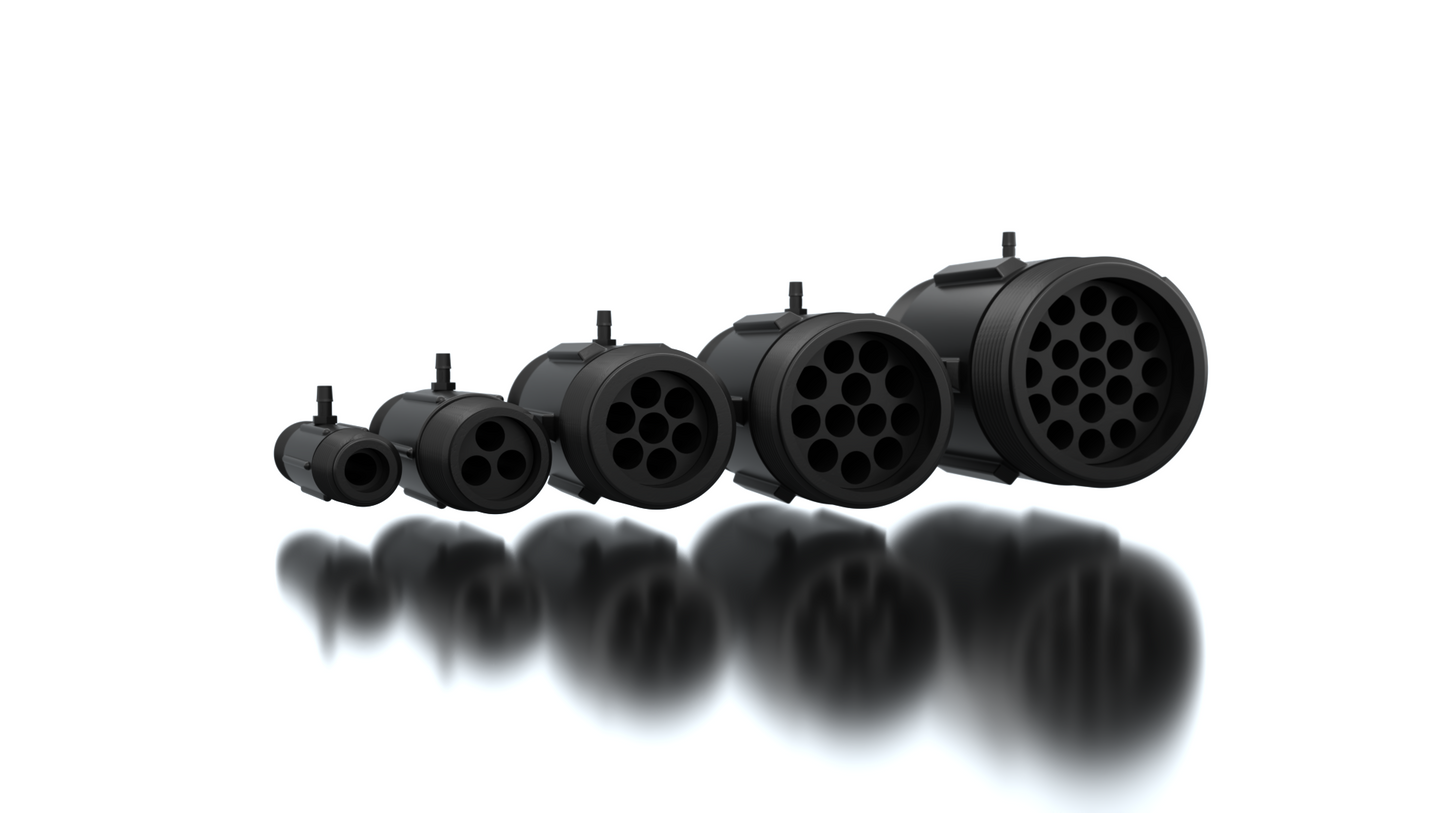

Revolutionize Your System

-

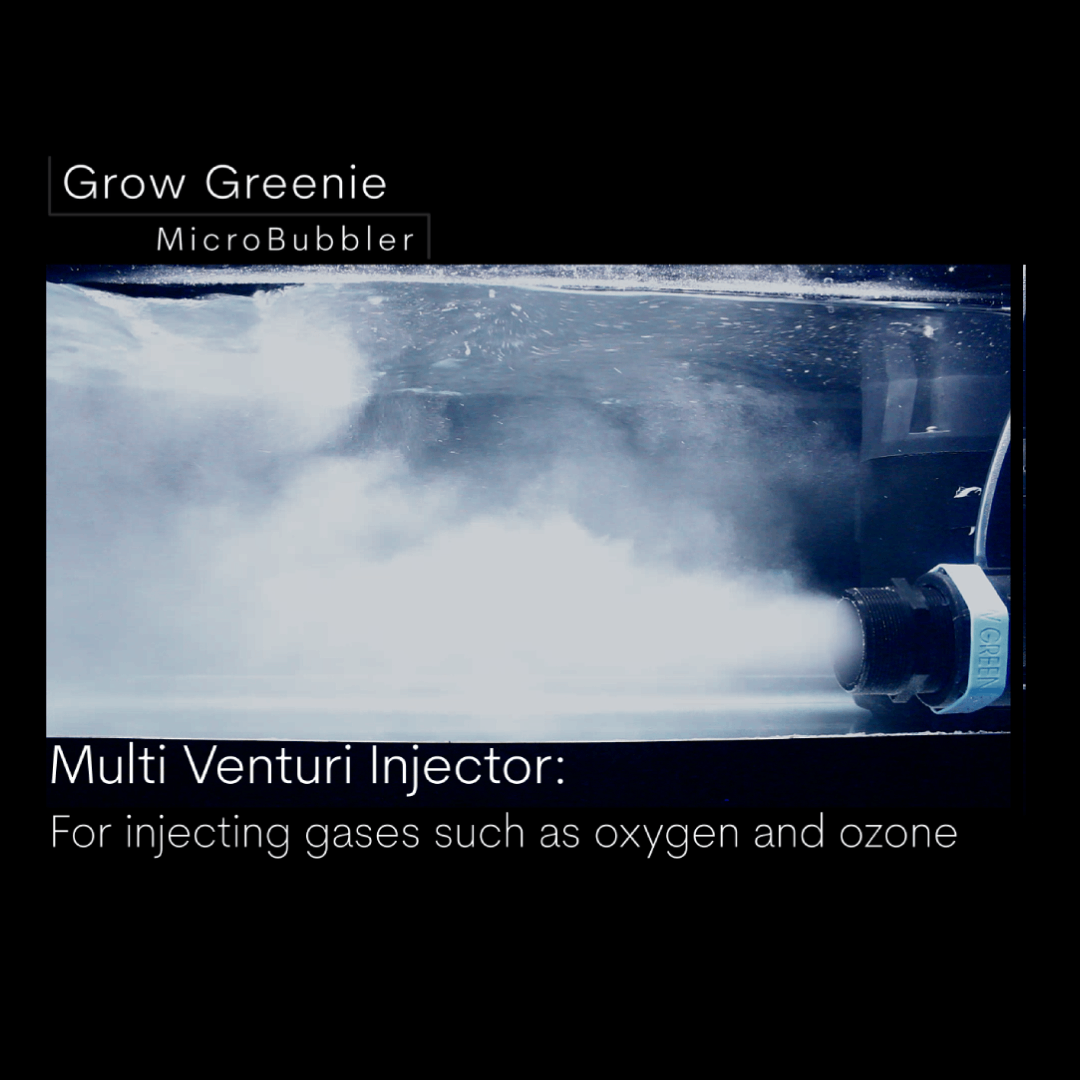

Microbubble Injector

Used for injection of gases or liquid fertilizers. After injection liquid fertilizers ensure that clean water is passed through the air tubing and device to keep it clean and unclogged.

-

Control the Bubble Size

By using a flow valve or flow meter you can control how fine of a bubble you want. Reducing air flow under .1 L/min will give you microbubbles.

-

Inline Tee or Jet Head

Use the MicroBubbler inline on piping or as a jet head in a tank or reservoir. Manufactured with MPT threaded connections.

-

Reduce Energy Costs

Save on expenses by eliminating the requirement for large and costly machinery or air compressors. Simply connect it to any water pump that meets recommended minimum flow rates.

See it in action

See it in action

MicroBubble Injection for Water Treatment

Discover the most cost-effective technique for injecting oxygen or ozone into your tank or reservoir.

MicroBubble Injection for Hydroponics & Agriculture

When the oxygen demand is high, turn to the best performing nozzle in the industry.